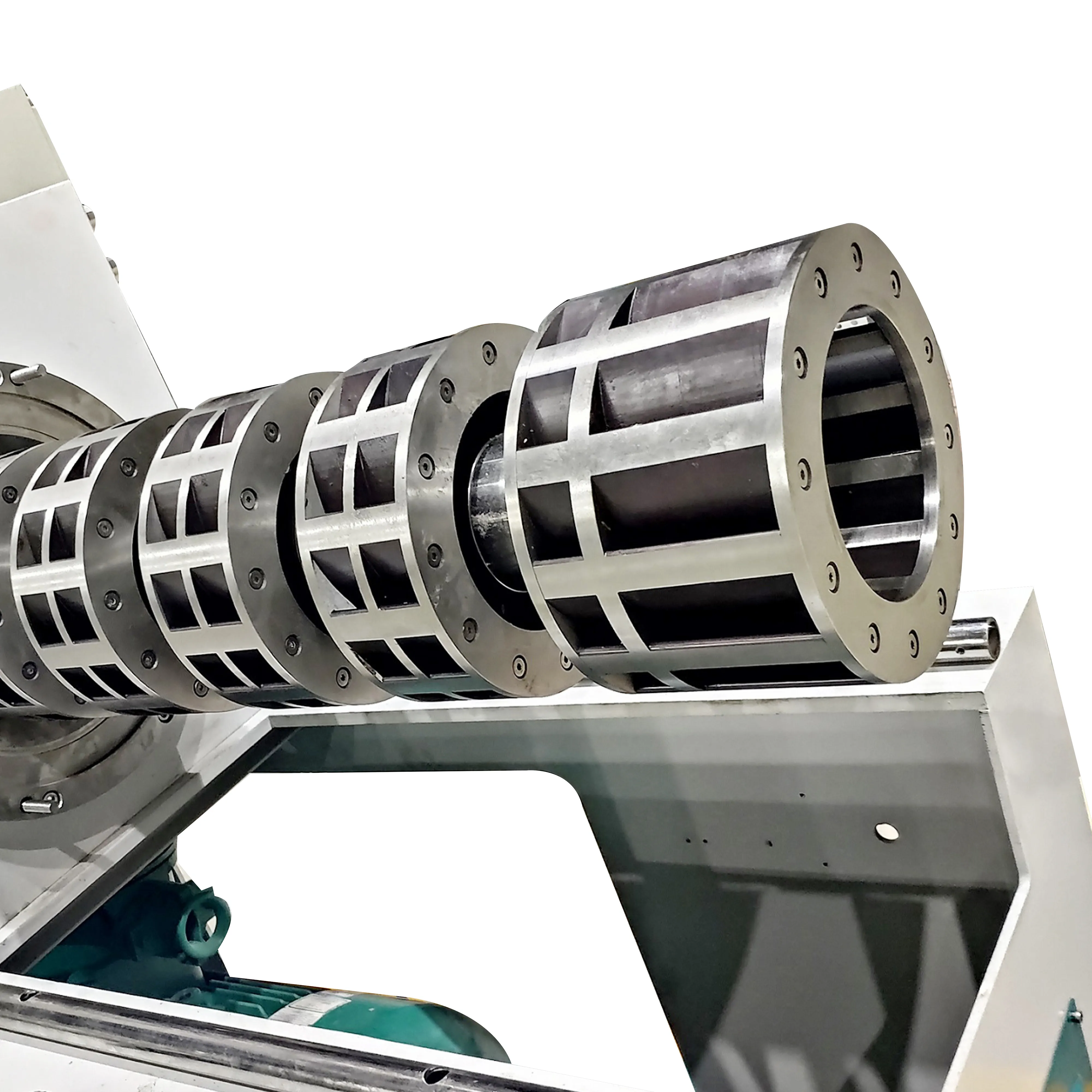

RTSM-CJ(D) Industrial Turbine-Type Static Sand Mill

This equipment enables efficient industrial production from micron to nano scale, featuring uniform particle size and low energy consumption.

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

description1

Zipper closure

1/4 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them in

place during workout

Product Introduction

This equipment is a high-energy, high-grade grinding machine. It ensures more uniform particle size and high energy utilization efficiency, suitable for the industrial production of materials with medium-low viscosity, good fluidity, and requirements for micron-level and nano-level particle sizes.

Performance Features

1.Doubled efficiency

Compared with traditional disc-type sand mills, the grinding efficiency and energy utilization rate are increased by more than twice.

2.Excellent temperature control

The turbine bead-stirring delivers uniform and gentle energy, avoiding local overheating. It is suitable for low-melting-point materials and prevents creaming or agglomeration.

3.Uniform particle size

Especially proficient in precision grinding of nanomaterials, the finished product has a concentrated particle size distribution and stable quality.

4.Good foam suppression

Effectively controls the generation of bubbles, suitable for foaming-prone materials.

5.One-click operation

Supports direct formula input and automatic operation, reducing human error and ensuring product consistency.

6.Self-cleaning screen

Equipped with a self-cleaning function, it effectively solves the blockage problem and simplifies maintenance.

Application Fields

|

battery cathode and anode materials |

pesticides |

semiconductor materials |

MLCC |

Applied in industries such as battery cathode and anode materials, pesticides, semiconductor materials, and MLCC.

Technical Parameters

|

Model |

Grinding Chamber Volume(L) |

Power(kW) |

Rotation Speed(rpm) |

Grinding Media(mm) |

Zirconium Bead Usage(Kg) |

Production Capacity (Kg/h) |

Overall Dimensions(mm) |

Weight(Kg) |

|

RTSM-15CJ(D) |

15 |

30 |

0-3000 |

0.1-2 |

38 |

0-800 |

1650*1050*1800 |

1400 |

|

RTSM-30CJ(D) |

30 |

45 |

0-1500 |

0.1-2 |

75 |

0-1500 |

1750*1050*2000 |

1850 |

|

RTSM-60CJ(D) |

60 |

75 |

0-1500 |

0.1-2 |

150 |

0-3000 |

2550*1250*1950 |

2350 |

|

RTSM-90CJ(D) |

90 |

90 |

0-990 |

0.6-2 |

230 |

0-4000 |

2050*1250*2050 |

2550 |

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp)

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)