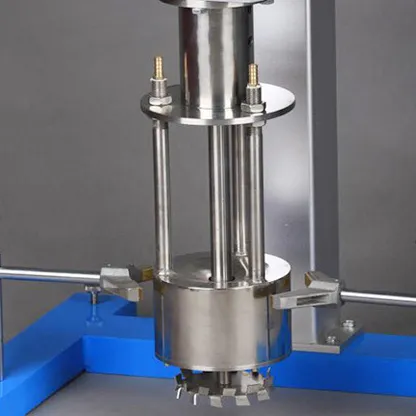

RTLL Laboratory Basket Mill

This is a grinding equipment that integrates grinding and dispersion, requiring no pre-dispersion and being easy to clean. It is specially designed for the R&D of small-batch, multi-variety nano-scale materials.

2.webp?x-oss-process=image/resize,w_100/quality,q_100)

2.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

The laboratory basket mill is an efficient wet grinding and dispersing equipment. Its core feature is that the grinding media (such as zirconium beads) are enclosed in a liftable basket-shaped grinding head. During operation, the grinding head is immersed in the slurry and rotates at high speed to achieve grinding, dispersing and mixing of materials. It eliminates the pre-dispersion step of traditional equipment, is easy to clean and change colors, and is very suitable for the research, development and preparation of small-batch, multi-variety nano-scale new materials in laboratories.

1.Stepless Frequency Speed Regulation with Digital Display

It features stepless speed adjustment via frequency control, with a digital display that shows the real-time speed. This allows for precise and intuitive control of the grinding head’s rotation speed, adapting to different material properties and requirements.

2.Customizable Polymer Basket Body: Solvent-Resistant, No Discoloration for White Materials

The basket body can be customized with high-performance polymer materials. This material is resistant to solvents (suitable for grinding solvent-based slurries) and prevents discoloration when processing white materials—effectively avoiding material contamination caused by basket body discoloration.

3.Detachable Basket Body for Easy Cleaning

The basket body is designed to be detachable. After use, it can be easily removed from the equipment for thorough cleaning, which saves time on cleaning operations and minimizes material residue—ideal for laboratory scenarios involving frequent material or color changes.

4.Integrated Dispersion, Grinding, and Mixing in One Step: Time and Labor Saving

It integrates dispersion, grinding, and mixing functions into a single operation. There is no need to transfer materials between different devices or perform separate processing steps, which significantly reduces operation time and labor intensity while ensuring consistent material processing quality.

|

biology |

pharmaceuticals |

cosmetics |

food |

paints |

inks |

It is suitable for research and development (R&D) and experiments in industries such as biology, pharmaceuticals, cosmetics, food, paints, inks, color pastes, dyes, and fertilizers.

|

Model |

Power |

Speed |

Processing Capacity |

Grinding Media |

Lifting Method |

|

RTLL-0.75 |

0.75 |

0-3000 |

5 |

0.8-2.0 |

Manual or Electric Lifting |

|

RTLL-2.2 |

2.2 |

0-3000 |

10 |

0.8-2.0 |

Manual or Electric Lifting |

2.webp?x-oss-process=image/resize)

2.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)