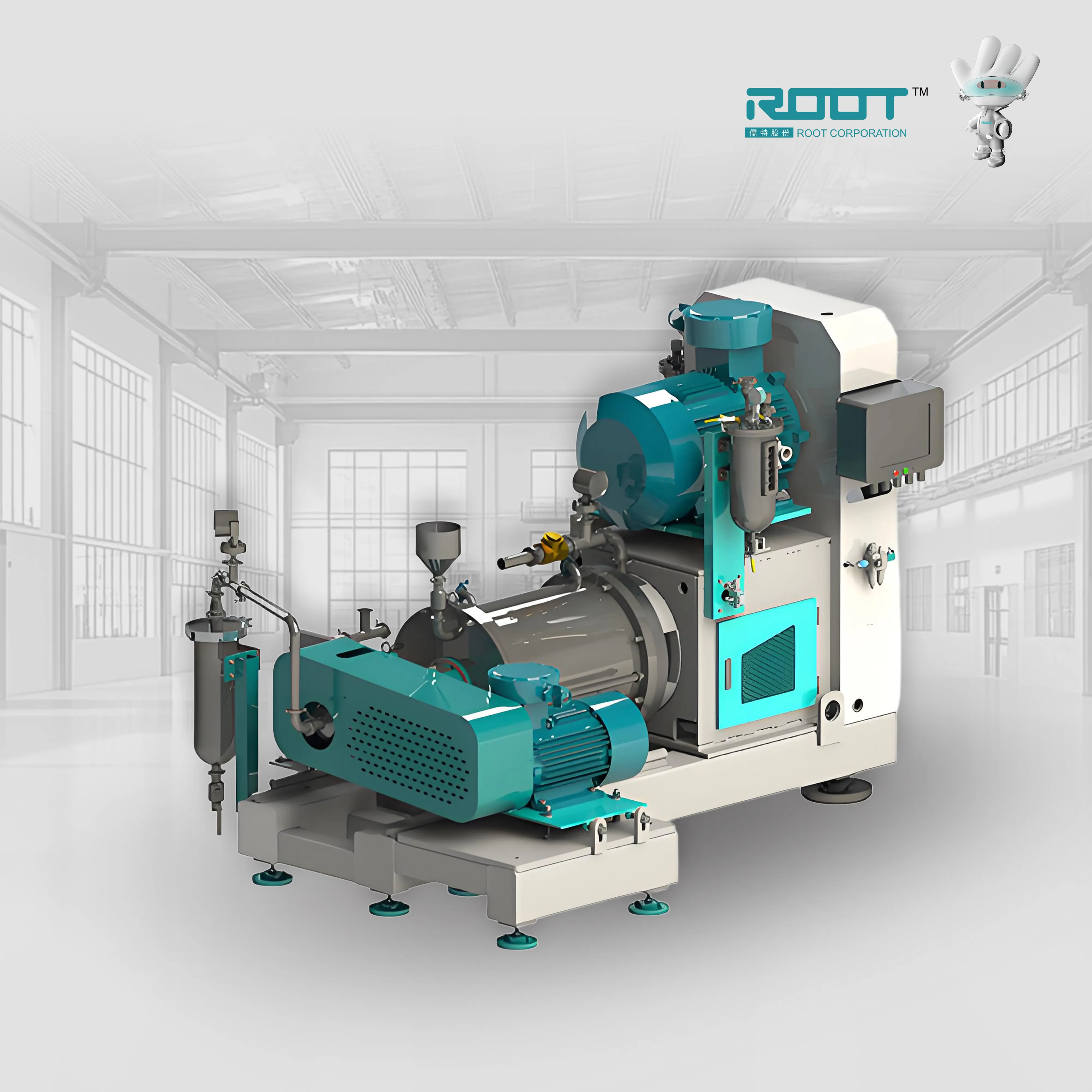

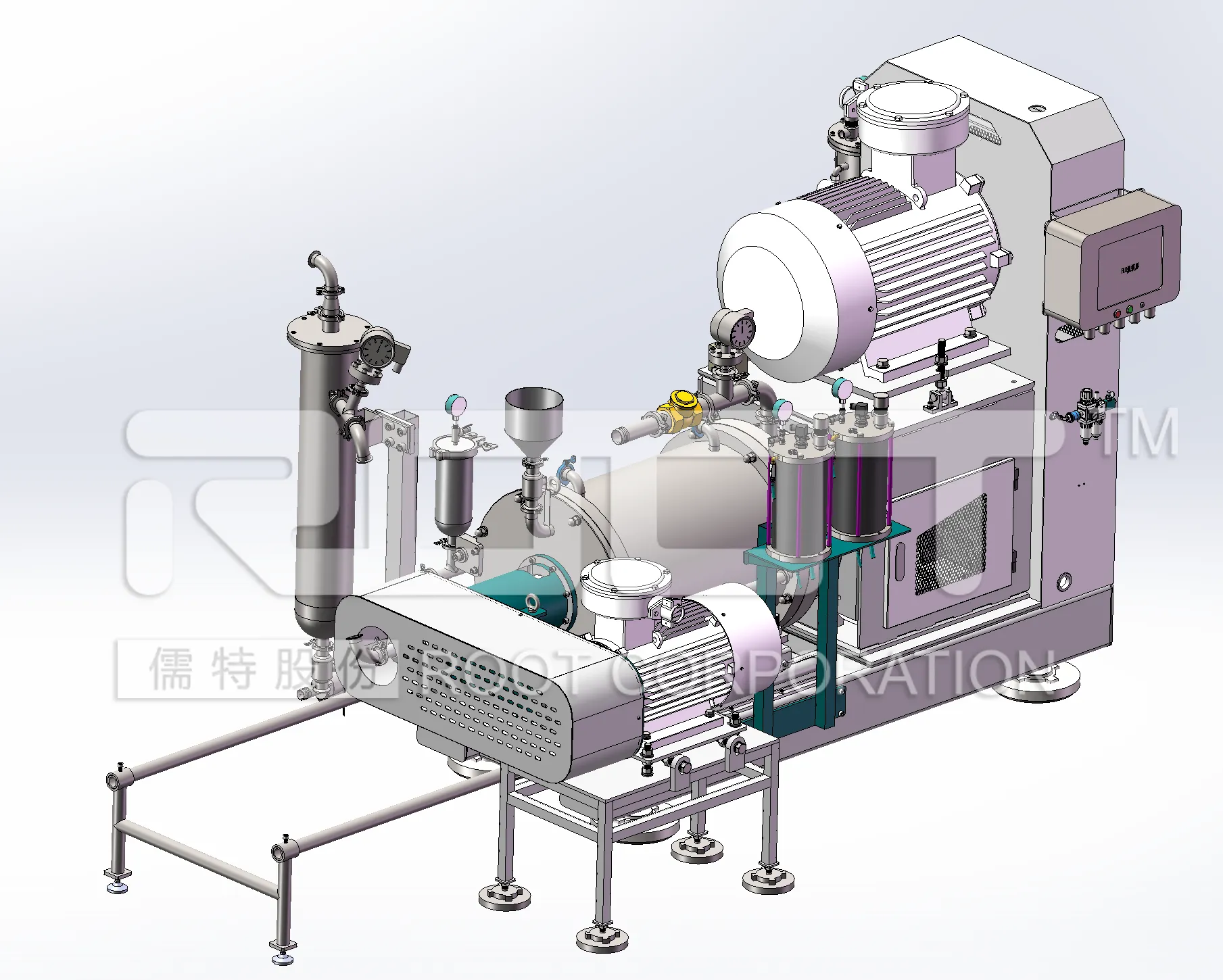

RTSM-BDD Dual-Drive Sand Mill

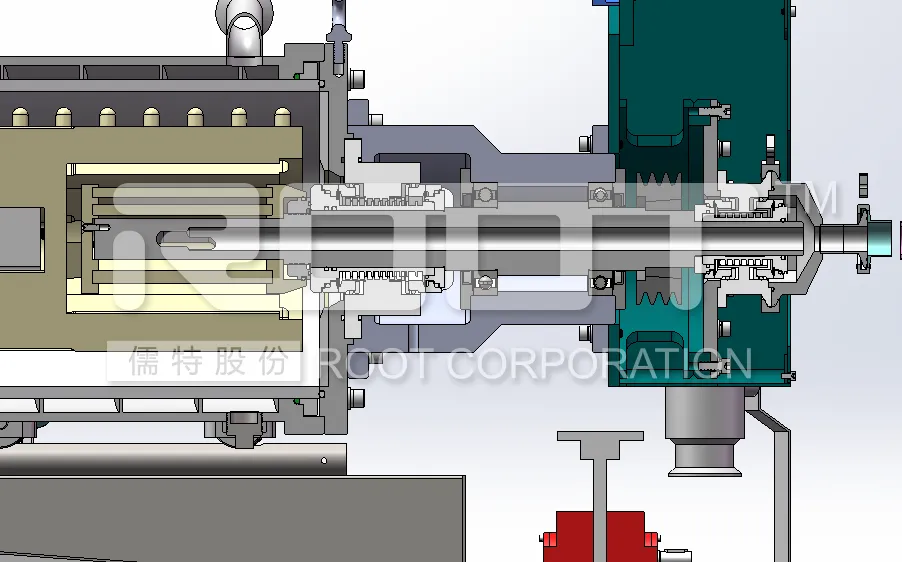

It is available in multiple models with capacities ranging from 30L to 150L. The sieve-free design is compatible with media below 0.05mm, enabling ultra-fine grinding down to below 80nm. It features no bead leakage, high efficiency and excellent temperature control, suitable for pilot-scale and mass production in industries such as silicon-carbon materials.

|

silicon-carbon materials |

silicon-oxygen materials |

digital inkjet |

MLCC |

Applied in industries such as silicon-carbon materials, silicon-oxygen materials, solid electrolytes, digital inkjet, MLCC, and nano-new materials.

|

Model |

RTSM-BDD30 |

RTSM-BDD60 |

RTSM-BDD90 |

RTSM-BDD150 |

|

Grinding Chamber Volume(L) |

30 |

60 |

90 |

90 |

|

Main Motor Power(kW) |

37/45 |

55/75 |

90/110 |

132/160 |

|

Separation Motor Power(kW) |

7.5 |

18.5 |

37 |

45 |

|

Rotation Speed(rpm) |

0-1500 |

0-1500 |

0-990 |

0-990 |

|

Grinding Media(mm) |

0.05-1 |

0.05-1 |

0.05-1 |

0.05-1 |

|

Zirconium Bead Usage(Kg) |

75-85 |

150-175 |

230-260 |

380-450 |

|

Production Capacity (Kg/h) |

0-1500 |

0-3000 |

0-5000 |

0-8000 |

|

Inner Cylinder Material |

Silicon Carbide/Alloy Steel |

Silicon Carbide/Alloy Steel |

Silicon Carbide/Alloy Steel |

Silicon Carbide/Alloy Steel |

|

Rotor Material |

Ceramic/Alloy Steel |

Ceramic/Alloy Steel |

Ceramic/Alloy Steel |

Ceramic/Alloy Steel |

|

Maximum Linear Speed (m/s)(m/s) |

16 |

16 |

16 |

16 |

|

Operation Control |

Touch Screen |

Touch Screen |

Touch Screen |

Touch Screen |

|

Screen Material |

None |

None |

None |

None |

|

Overall Dimensions (mm) |

2550*1250*1800 |

2850*1250*2050 |

2950*1350*2050 |

3200*1850*2650 |

|

Weight (Kg) |

1800 |

3000 |

4200 |

6000 |

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)