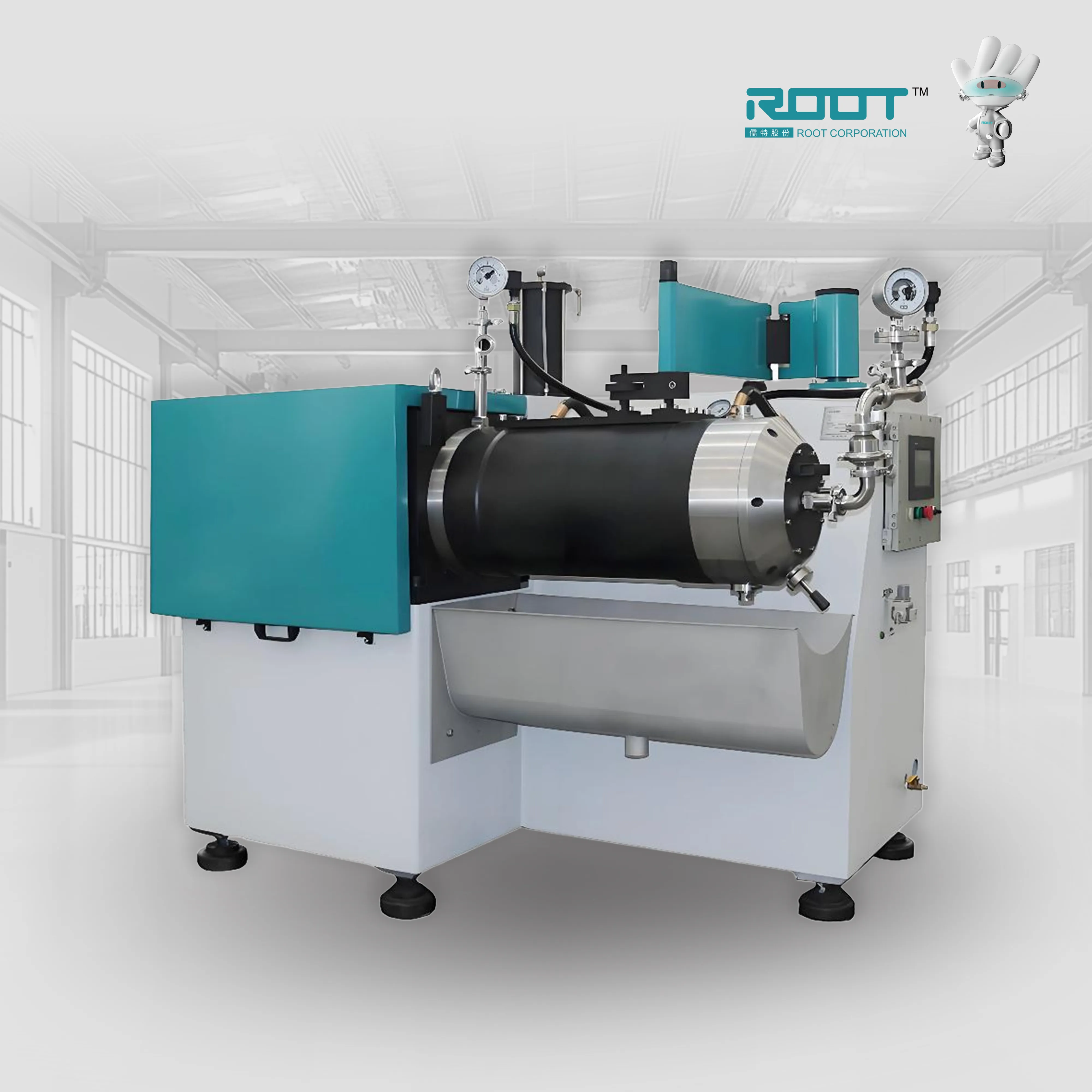

RTSM-AD Industrial Disc-type Dynamic Sand Mill

This is a continuous ultra-fine grinding equipment. Driven by high-speed disc sets, the medium generates intense shearing force, quickly grinding materials to micron or nano scale, and achieving efficient and precise grinding of products.

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

2.webp?x-oss-process=image/resize,w_100/quality,q_100)

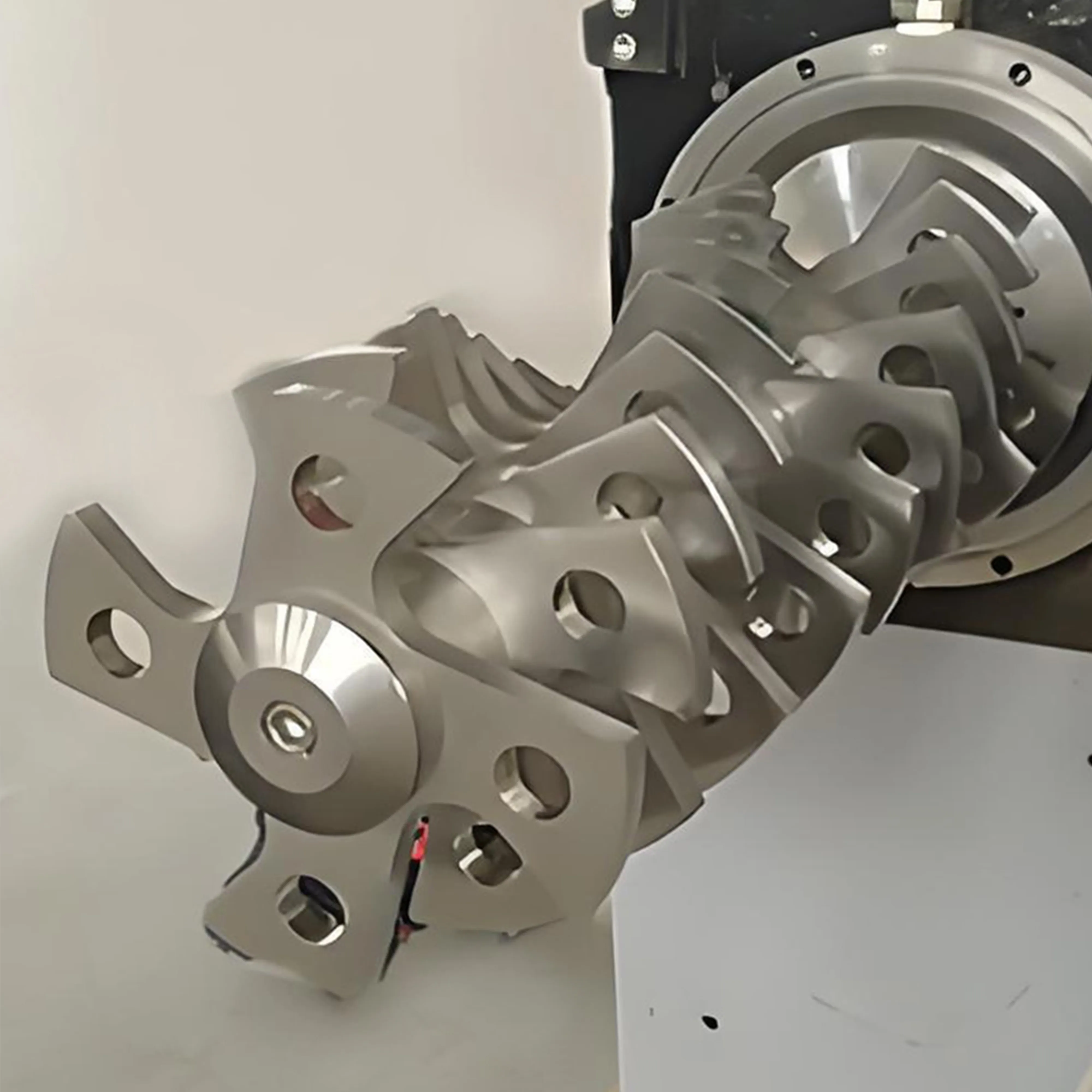

The industrial disc-type dynamic sand mill is a high-efficiency, continuous wet ultra-fine grinding equipment. Its core working principle is that the high-speed rotating grinding disc set drives grinding media (such as zirconia beads) to generate intense shearing, impact and friction, thereby disaggregating particle agglomerates in materials and grinding them to micron or even nanometer level in an extremely short time. It is a key equipment to achieve high fineness and excellent dispersibility of products.

1.Stable Mechanical Seal Performance

It adopts an independent fixed external flow design, which avoids the impact of equipment vibration and torque changes, prevents material contamination of the cooling liquid, and ensures reliable operation.

2.Efficient Cooling System

Through precisely calculated flow guide channels, high-conductivity pulleys, and a multi-layer cooling design, it achieves dead-angle-free cooling and effectively controls temperature.

3.Smooth Discharge Without Clogging

Equipped with a high-flow dynamic slotted separator, it features a large flow area, supports 0.3–0.8mm slots and 0.8–2.0mm grinding media, and avoids clogging.

4.Efficient Grinding

It adopts a new disc-type grinding structure, which realizes effective dispersion and shearing through high-speed relative motion. Combined with a dynamic rotor separation filter, it ensures product quality.

|

pesticide suspensions |

paints |

inks |

automotive primers |

coatings |

It is applied in industries such as pesticide suspensions, paints, inks, automotive topcoats, automotive primers, and coatings.

|

Model |

Grinding Chamber Volume(L) |

Power(kW) |

<Rotational Speed(rpm) |

Grinding Media(mm) |

Zirconia Beads Usage Amount(Kg) |

Production Capacity (Kg/h) |

Overall Dimensions(mm) |

Weight(Kg) |

|

RTSM-10 |

10 |

15 |

0-1500 |

0.8-2.0 |

25 |

0-500 |

1500*950*1250 |

750 |

|

RTSM-30 |

30 |

30 |

0-1500 |

0.8-2.0 |

75 |

0-1000 |

1650*1050*1650 |

1050 |

|

RTSM-50 |

50 |

50 |

0-1500 |

0.8-2.0 |

125 |

0-1000 |

1750*1100*1750 |

1250 |

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

2.webp?x-oss-process=image/resize)

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)