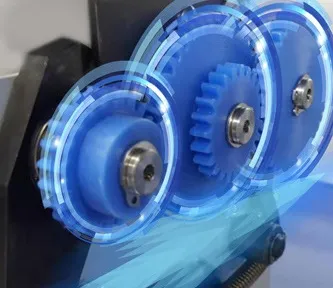

RTSY Hydraulic Three-Roll Mill

Leveraging three rolls and a hydraulic system, it achieves material rolling and grinding with stable and precise pressure. It features stepless pressure adjustment, high efficiency and low vibration, suitable for multiple industries with a variety of models available.

A hydraulic three-roll mill is a device that rolls, calenders, or crushes materials using three horizontally placed rollers and a hydraulic system. Its core principle is to use a hydraulic cylinder to provide strong and precise pressure, driving the movable roller to cooperate with the other two fixed rollers to form an adjustable gap. When materials pass through the roller gap, they are processed into the required thickness or fineness under the action of high pressure, shearing, and extrusion.

|

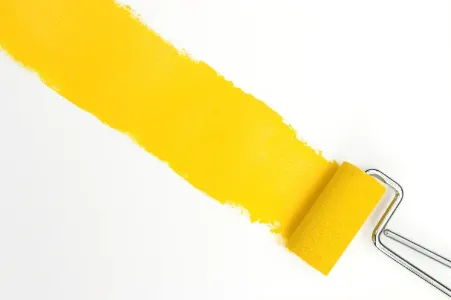

coatings |

inks |

paints |

rubber |

cosmetics |

food |

It is suitable for industries such as coatings, inks, paints, rubber, cosmetics, and food.

|

Model |

Roller diameter(mm) |

Working length(mm) |

Main motor power(Kw) |

Roller Material |

Hydraulic Motor Power (Kw) |

Hydraulic System (MPa) |

Overall Dimensions (mm) |

Weight (Kg) |

|

RTSY-150 |

150 |

300 |

5.5/7.5 |

Wear-Resistant Alloy/Zirconia/Alumina |

0.75 |

6.3 |

1150*990*1650 |

850 |

|

RTSY-200 |

200 |

300 |

7.5 |

Wear-Resistant Alloy/Zirconia/Alumina |

0.75 |

6.3 |

1250*1050*1650 |

1260 |

|

RTSY-260 |

260 |

650 |

22/30 |

Wear-Resistant Alloy/Zirconia/Alumina |

1.5 |

6.3 |

1650*1250*1450 |

2100 |

|

RTSY-400 |

400 |

800 |

37/45 |

Wear-Resistant Alloy/Zirconia/Alumina |

1.5 |

6.3 |

2100*1750*1550 |

4500 |

|

RTSY-400-1000 |

400 |

1000 |

45/55 |

Wear-Resistant Alloy/Zirconia/Alumina |

1.5 |

6.3 |

2300*1750*1550 |

4950 |

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)