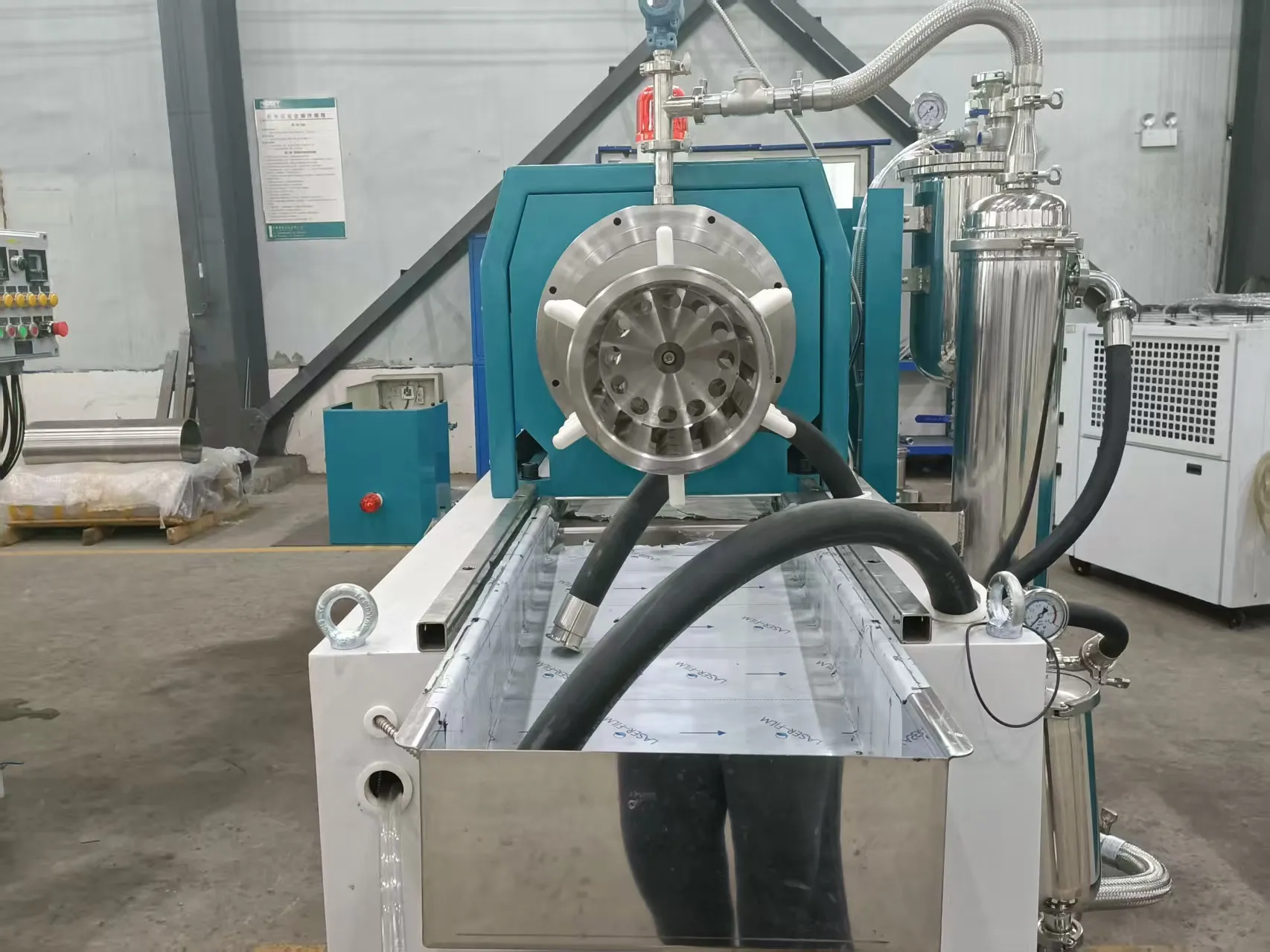

RTSM-AJ Industrial Disc-type Static Sand Mill

This equipment is specially designed for industrial mass production. Adopting centrifugal sieve discharge and an optimized disc structure, it achieves large flow rate and high output.

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

It is specially developed for large-volume industrial production. Adopting a centrifugal screen discharge structure, the equipment achieves a larger flow rate per unit time and higher finished product output. In industrial production, it can realize different grinding processes such as single-machine circulation grinding, single-machine cylinder reversing grinding, and dual-machine series grinding. The optimized disc structure and discharge structure result in better grinding fineness of finished products and more uniform particle size distribution, reaching D90 < 3μm.

|

industrial-scale production |

It is widely used in the industrial-scale production of water-based, oil-based, and low-viscosity materials.

|

Model |

Grinding Chamber Volume(L) |

Power(kW) |

Rotational Speed(rpm) |

Grinding Media(mm) |

Zirconia Beads Usage Amount(Kg) |

Production Capacity (Kg/h) |

Overall Dimensions(mm) |

Weight(Kg) |

|

RTSM-15 |

15 |

22 |

0-1500 |

0.3-2.0 |

38 |

0-800 |

1460*1000*1400 |

650 |

|

RTSM-30 |

30 |

30 |

0-1500 |

0.3-2.0 |

75 |

0-1500 |

1950*950*1650 |

650 |

|

RTSM-60 |

60 |

45/37 |

0-1500 |

0.3-2.0 |

150 |

0-2500 |

2000*950*1900 |

1500 |

|

RTSM-100 |

100 |

55/75 |

0-1500 |

0.3-2.0 |

250 |

0-3500 |

2580*1280*1970 |

3000 |

|

RTSM-300 |

300 |

90/110 |

0-990 |

0.3-2.0 |

700 |

0-5000 |

3600*1800*2500 |

4200 |

|

RTSM-1000 |

1000 |

315/355 |

0-990 |

0.3-2.0 |

2000 |

0-10000 |

6500*2050*3600 |

17000 |

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp)

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)