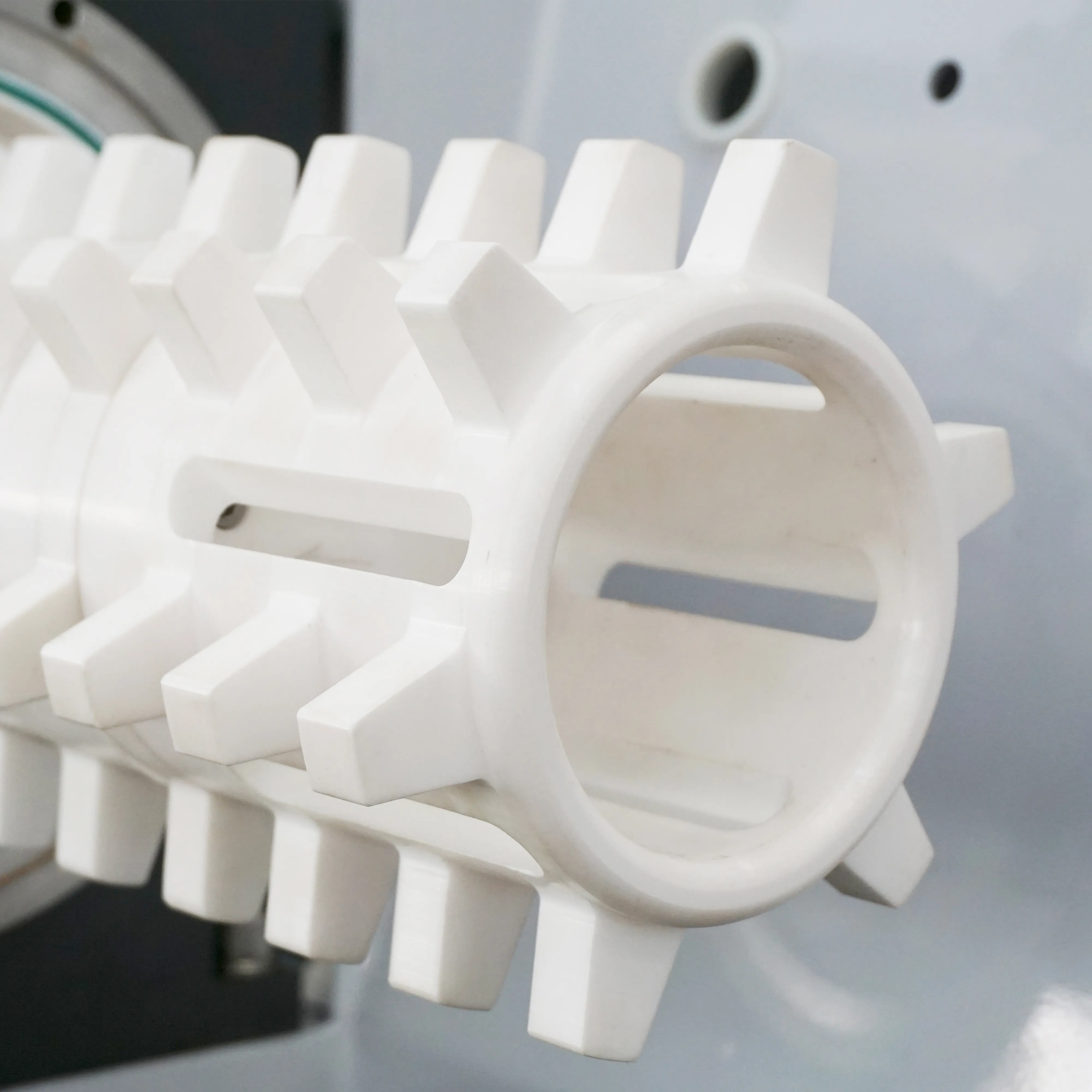

RTSM-BJ(D) Industrial Pin-Type Static Sand Mill

This equipment has improved the pin material, layout and sieve filtration area of traditional sand mills, significantly enhancing grinding efficiency and output.

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

-调冷色.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

|

battery cathode and anode materials |

titanium dioxide |

pesticides |

water-soluble fertilizers |

Suitable for industrial production of materials with medium to low viscosity, good fluidity, and requiring micron and nanoscale particle sizes. Such as battery cathode and anode materials, titanium dioxide, pesticides, water-soluble fertilizers, color pastes, organic pigments, chemical fiber color pastes, etc.

|

Model |

Grinding Chamber Volume(L) |

Power(kW) |

Rotation Speed(rpm) |

Grinding Media(mm) |

Zirconium Bead Usage(Kg) |

Production Capacity (Kg/h) |

Overall Dimensions(mm) |

Weight(Kg) |

|

RTSM-6BJ(D) |

6 |

15 |

0-3000 |

0.1-2 |

15 |

0-600 |

1250*1000*1300 |

700 |

|

RTSM-10BJ(D) |

10 |

18.5/22 |

0-1500 |

0.1-2 |

25 |

0-800 |

1700*1000*1400 |

1000 |

|

RTSM-30BJ(D) |

30 |

37/45 |

0-1500 |

0.1-2 |

75 |

0-1500 |

1900*1050*1800 |

1400 |

|

RTSM-60BJ(D) |

60 |

55/75 |

0-1500 |

0.1-2 |

150 |

0-3000 |

2050*950*2050 |

2600 |

|

RTSM-100BJ(D) |

100 |

90/110 |

0-990 |

0.1-2 |

230 |

0-5000 |

2050*1250*2050 |

3500 |

|

RTSM-150BJ(D) |

150 |

132/160 |

0-990 |

0.1-2 |

380 |

0-8000 |

3000*1700*2650 |

4000 |

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

-调冷色.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp)

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)