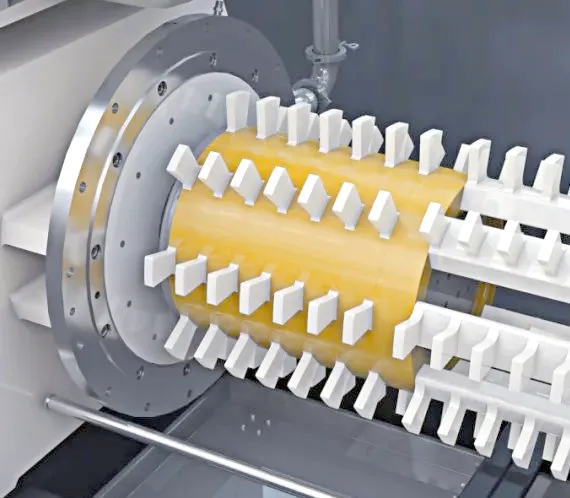

RTSM-BD Industrial-Grade Pin-Type Dynamic Sand Mill

This equipment is widely used for micron to nano-scale grinding. Adopting dynamic/static gap discharge, it can handle medium to high viscosity materials.

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

It is widely used for micron-level, sub-micron-level, and nano-level grinding. Adopting dynamic and static gap discharge, it can effectively handle medium-to-high viscosity materials. Based on the research and development of comprehensive fluid mechanics and mechanical properties, it is equipped with high-efficiency pin rotor structures and pin-block rotor structures, which are suitable for different viscosities, different sizes, different grinding finenesses, and different grinding processes.

1.Reliable Operation

It adopts self-developed mechanical seals with excellent sealing performance. Cooling media can be selected according to material properties to prevent contamination.

2.Humanized Design

It features an exclusive drive adjustment design for easy maintenance and overhaul; the quick-connect pipelines allow easy disassembly. Equipped with anti-freezing and feed filtration devices, it adapts to low-temperature environments in northern regions and prevents clogging.

3.Wide Viscosity Adaptability

With dynamic discharge, it supports materials with a maximum viscosity of 20000 cps.

4.Intelligent Self-Protection

It monitors parameters such as water pressure, air pressure, temperature, and liquid level in real time. In case of abnormalities, it automatically shuts down and triggers an alarm.

.webp)

|

inks |

pesticides |

automotive paints |

It is suitable for materials with low, medium, and high viscosity ranges, and is applied in industries such as inks, pesticides, automotive paints, wood coatings, and anti-corrosion paints.

|

Model |

Grinding Chamber Volume(L) |

Power(kW) |

Rotational Speed(rpm) |

Grinding Media(mm) |

Zirconia Beads Usage Amount(Kg) |

Production Capacity (Kg/h) |

Overall Dimensions(mm) |

Weight(Kg) |

|

RTSM-1 |

1 |

4 |

0-3000 |

0.8-2.0 |

2.5 |

0-30 |

800*800*850 |

250 |

|

RTSM-10 |

10 |

18.5 |

0-1500 |

0.8-2.0 |

25 |

0-500 |

1700*1000*1250 |

950 |

|

RTSM-30 |

30 |

37 |

0-1500 |

0.8-2.0 |

75 |

0-1000 |

2050*1250*1750 |

1500 |

1.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp)

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)