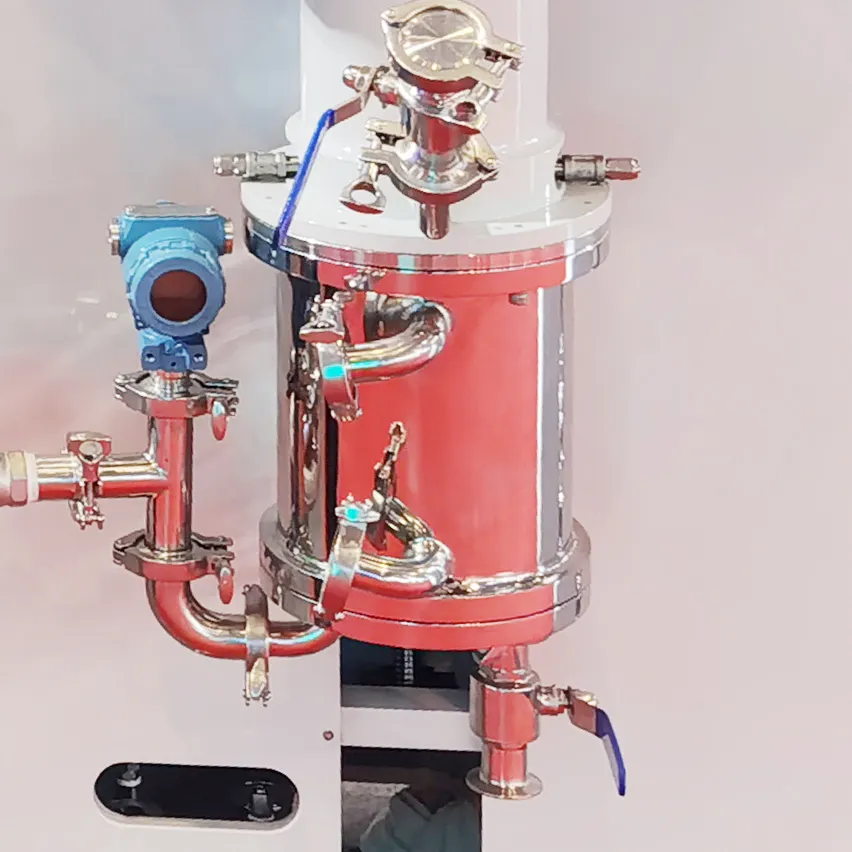

RTSM Laboratory Sand Mill

This equipment adopts two innovative structures: inorganic sealing and sieve-free centrifugal discharge. It eliminates leakage and reduces maintenance costs; supports the use of 0.1mm microbeads, improves grinding efficiency, and ensures finer and more uniform finished products.

.webp?x-oss-process=image/resize,w_100/quality,q_100)

It adopts an inorganic sealing structural design, which can completely solve the problems of mechanical seal leakage and damage in the use of traditional sand mills, thereby significantly reducing mechanical maintenance costs. With a sieve-free centrifugal separation discharge method, it can use zirconia beads with a minimum diameter of 0.1-0.2mm, which enhances grinding efficiency, makes material particles finer and more uniform, and achieves a more ideal particle size distribution.

|

scientific research |

laboratory formula research |

small-batch sample production |

It is suitable for scientific research, laboratory formula research, and small-batch sample production in universities, research institutions, and production-oriented enterprises.

|

Model |

Grinding Chamber Volume(L) |

Power(kW) |

Rotational Speed(rpm) |

Grinding Media(mm) |

Zirconia Beads Usage Amount(Kg) |

Production Capacity (Kg/h) |

Overall Dimensions(mm) |

Weight(Kg) |

|

RTLM-1.0 |

1 |

5.5 |

0-3000 |

0.1-2 |

2.5 |

0-100 |

1100*750*1050 |

450 |

|

RTLM-2.0 |

2 |

7.5 |

0-3000 |

0.1-2 |

5 |

0-200 |

1280*1310*1550 |

800 |

|

RTLM-5.0 |

5 |

15 |

0-1500 |

0.1-2 |

38 |

0-600 |

1300*1350*1750 |

1250 |

|

RTLM-30 |

30 |

45 |

0-1500 |

0.1-2 |

75 |

0-1500 |

1700*1500*2600 |

2600 |

.webp?x-oss-process=image/resize)

.webp)

.webp)

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)