RTSM-BJ Laboratory Sand Mill

Optimized structure and materials endow it with easy operation, efficient grinding and industrial scalability, precisely adapting to scientific research and lab-scale production.

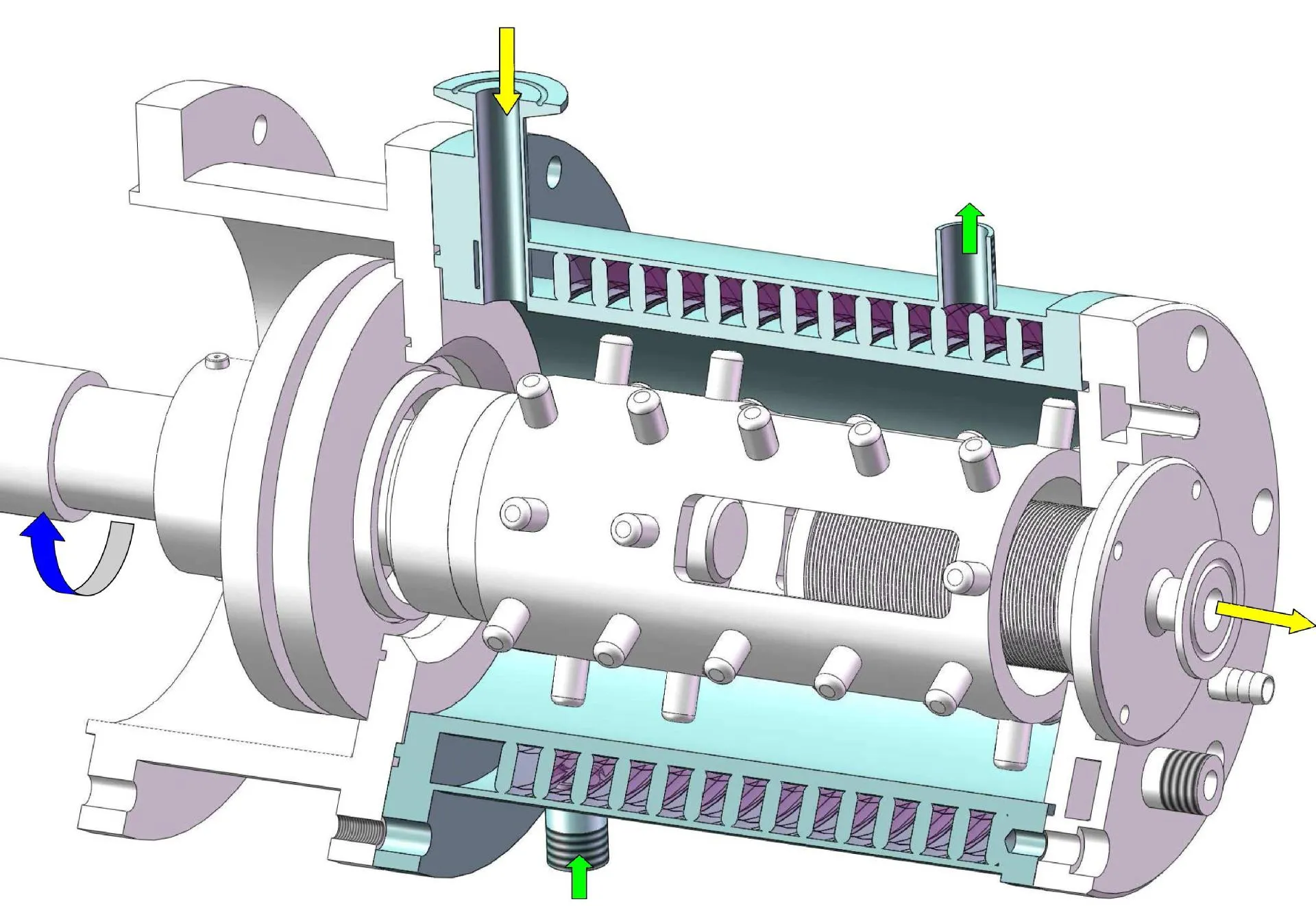

This new series of pin-type grinding mills has undergone targeted optimization for the core pin material and arrangement structure, achieving a perfect combination of a lightweight body and user-friendly operation. It not only offers high grinding efficiency and excellent results but also ensures outstanding industrial scalability of experimental outcomes. We provide two precisely adapted models, which can fully meet the needs of various application scenarios such as experimental research and small-batch trial production in universities and research institutes.

1.Stable Operation & Anti-Pollution Design

It boasts excellent performance and stable, reliable operation. Cooling media can be flexibly selected according to material characteristics, effectively preventing cross-contamination during the grinding process.

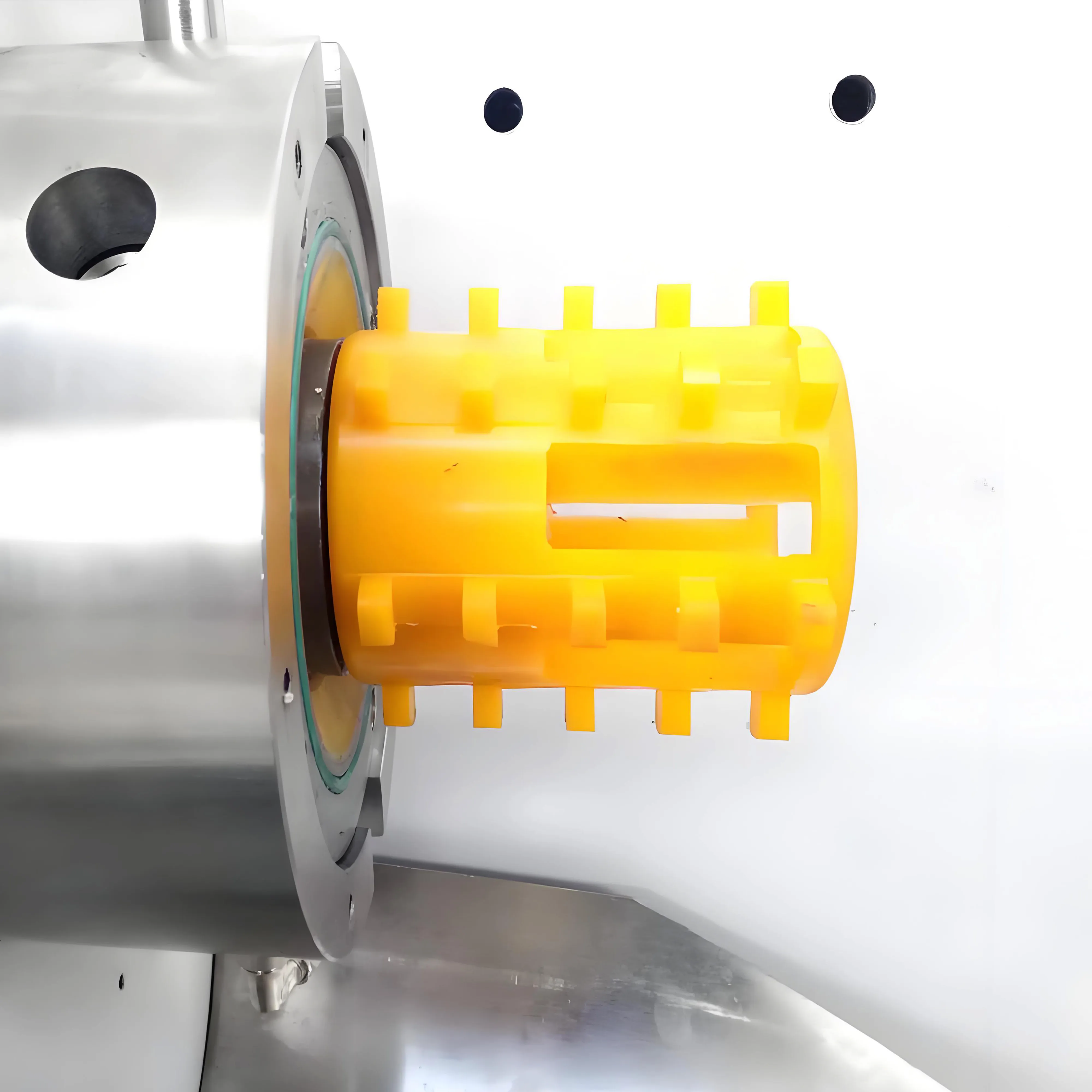

2.Lightweight Structure & Easy Operation

The overall weight of the machine is controlled between 50–65kg, facilitating movement and placement in the laboratory. The operation interface is concise and intuitive, supporting knob speed regulation for quick mastery by experimenters. The structural design also considers maintainability, making daily maintenance simple.

3.Industrial Scalability of Experimental Data

The structure and design of the laboratory model are derived from the proportional reduction of industrial-grade sand mills, ensuring that the grinding data obtained from experiments can be directly used for process scaling and parameter reference in industrial-grade production.

4.High-Efficiency Grinding

The high-speed rotation of the rotor drives strong relative movement between materials and grinding media, achieving full dispersion, shearing and grinding of particles.

|

scientific research |

laboratory formula research |

small-sample production |

Suitable for scientific research, laboratory formula research and small-sample production in universities, research institutions and production-oriented enterprises.

|

Model |

Grinding Chamber Volume(L) |

Power(kW) |

Rotation Speed(rpm) |

Grinding Media(mm) |

Zirconium Bead Usage(Kg) |

Production Capacity (Kg/h) |

Overall Dimensions(mm) |

Weight(Kg) |

|

RTSM-0.08BJ |

0.08 |

2.2 |

0-5000 |

0.2-1 |

0.2 |

0.1-0.3 |

450*280*500 |

50 |

|

RTSM-0.2BJ |

0.2 |

1.1 |

0-2800 |

0.3-0.8 |

0.45 |

0.3-0.8 |

650*400*890 |

65 |

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

1.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)