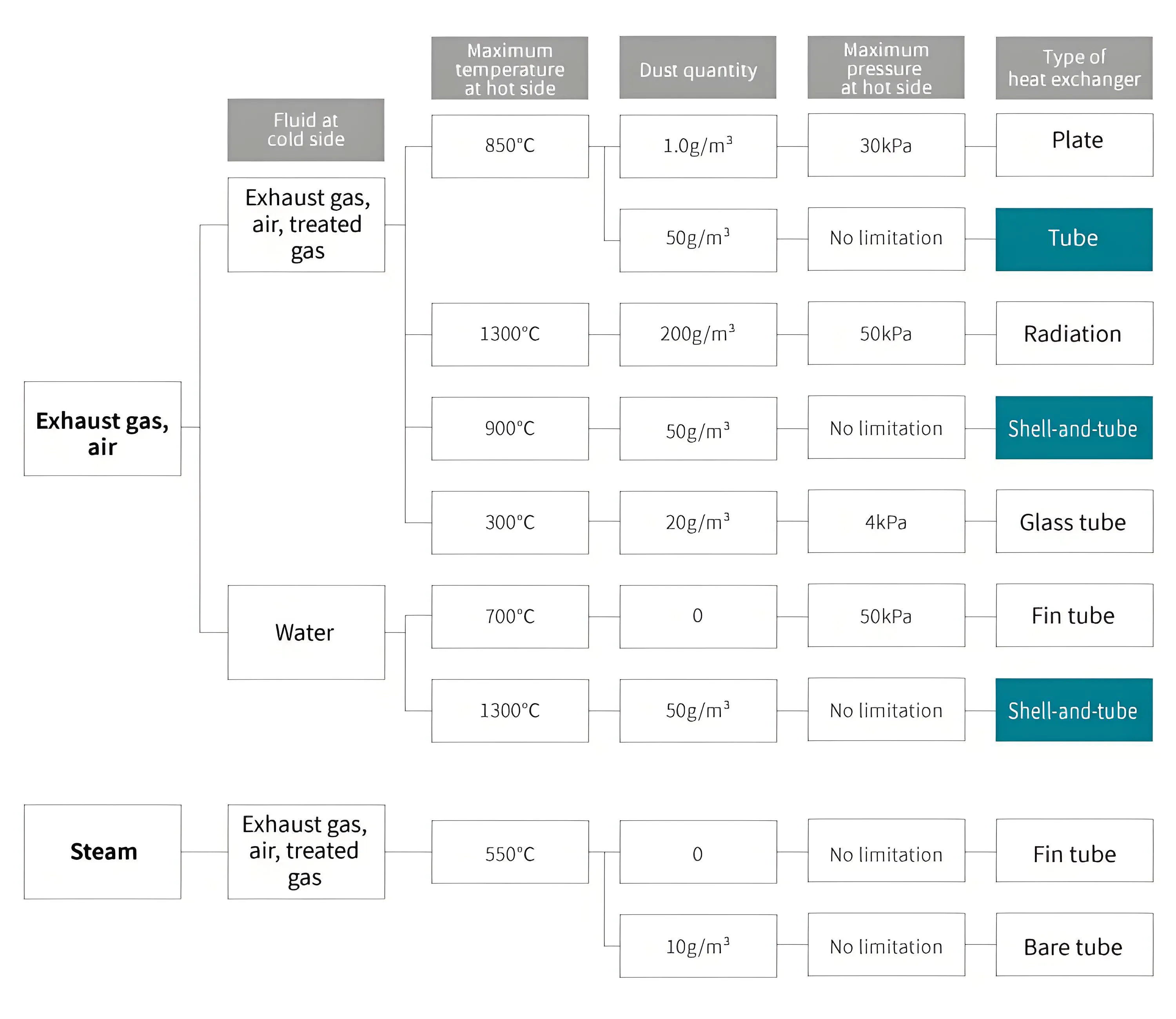

Shell-and-Tube Heat Exchanger

This product is designed for waste gas heat recovery from combustion. Different media correspond to different maximum temperatures, making it suitable for various industrial environmental protection equipment.

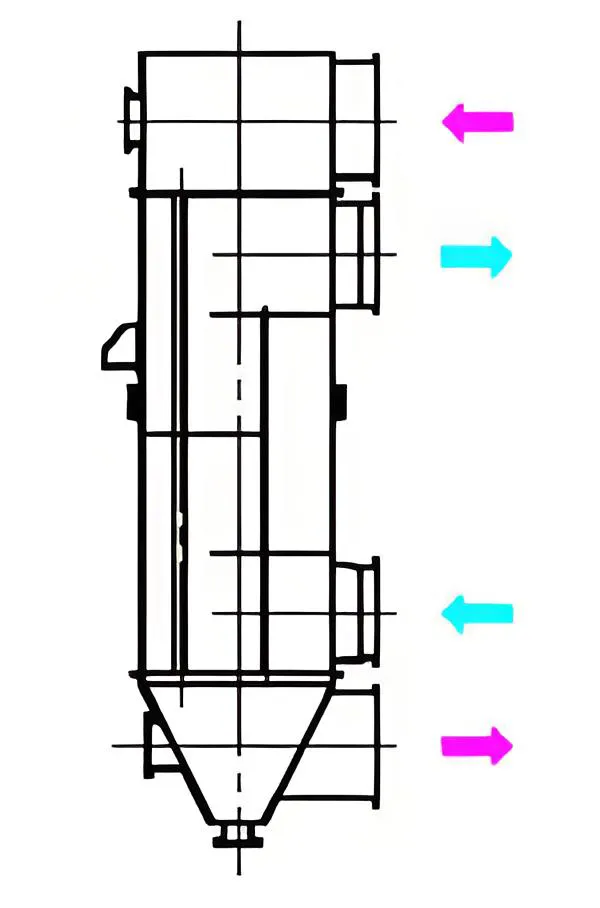

This heat exchanger is used for waste gas heat recovery from combustion. When the medium is air or gas, the maximum inlet temperature for heat release is 850–900°C; when the medium is water, the maximum inlet temperature can reach 1300°C. The shell is a high-temperature-resistant cylinder, and the expansion difference between the tubes and tube sheet is adjusted through a telescopic joint.

1.Targeted Heat Recovery:

Specifically designed for combustion exhaust heat recovery, with a clear functional purpose suitable for relevant heat recovery scenarios.

2.Wide Temperature Range Adaptability:

Different media correspond to different high-temperature limits, with the maximum heat release inlet temperature reaching 1300°C, offering strong temperature resistance.

3.Good Structural Compatibility:

The cylindrical shell is resistant to high temperatures, and the telescopic joint can adjust the expansion difference between the tubes and tube sheet to ensure structural stability.

|

Sludge Treatment |

Industrial Energy |

Chemical Production |

Waste Treatment |

1.Sludge Treatment:

Industrial waste sludge treatment equipment, wastewater sludge treatment equipment

2.Industrial Energy:

Industrial furnace waste heat recovery equipment

3.Chemical Production:

Chemical plant production equipment

4.Waste Treatment:

Industrial waste incineration equipment