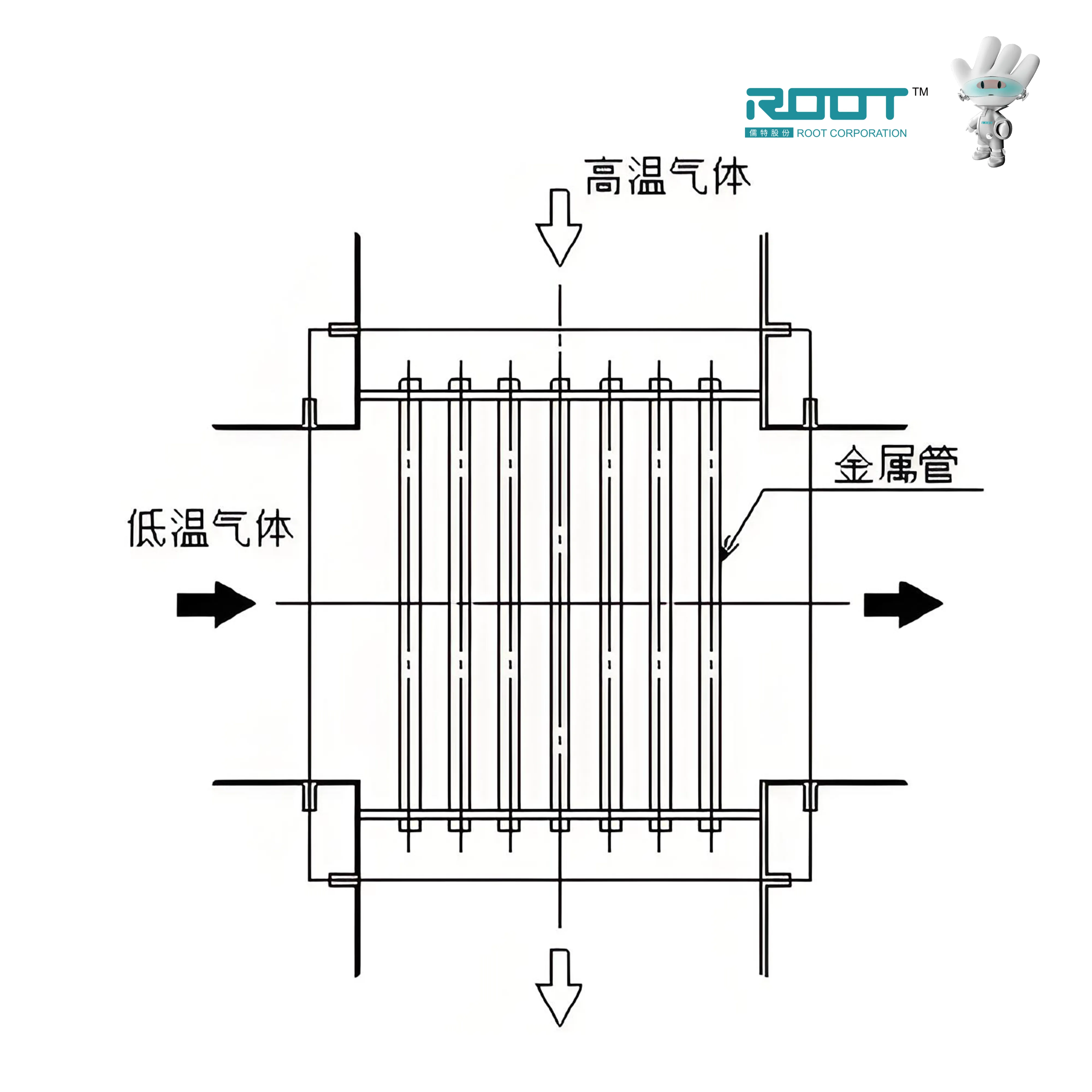

Dust Adhesion Prevention Device

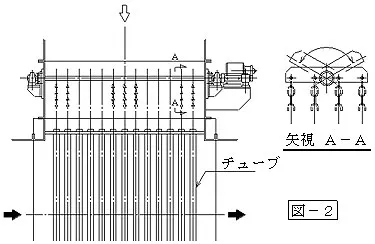

This device addresses the problem of dust accumulation inside tubes that causes blockages and reduces heat transfer efficiency. It uses multi-directional chain oscillation inside the tubes to remove and prevent dust. The cleaning cycle, originally required once every 1-2 months, can be extended to once every 1-2 years, reducing equipment downtime and costs.

1.Effective Dust Removal:

By oscillating chains vertically, horizontally, and circumferentially, combined with gas flow, it effectively eliminates and prevents dust adhesion inside the tubes, reducing blockages.

2.Significantly Reduces Maintenance Costs:

The cleaning cycle is greatly extended, avoiding frequent shutdowns (previously required about 3 days for cleaning), saving time, labor, and operational losses.

3.Flexible and Adjustable Operation:

Motor speed (30~90 rpm, standard 60 rpm) can be adjusted via a relay, and a timer can set idle periods to adapt to different operating conditions.

|

Waste Treatment |

Industrial Furnaces |

1.Waste Treatment:

Waste incineration equipment, industrial waste treatment tubular heat exchangers

2.Industrial Furnaces:

Tubular heat exchangers supporting industrial furnaces in the mining industry