Bellows-Type Heat Exchanger

This product is mainly used for gas-to-gas heat exchange, focusing on heat recovery in scenarios such as waste treatment and industrial waste management.

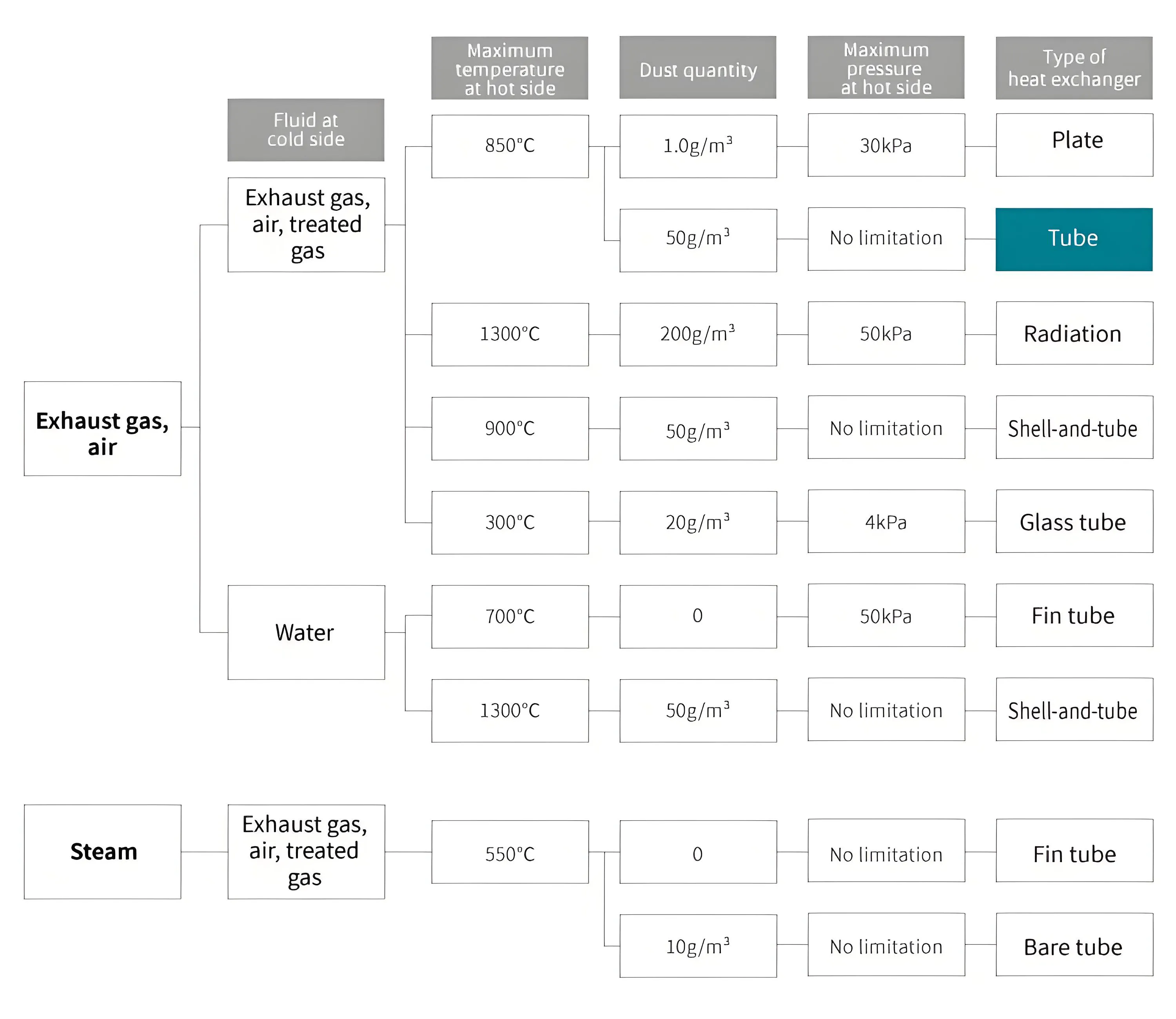

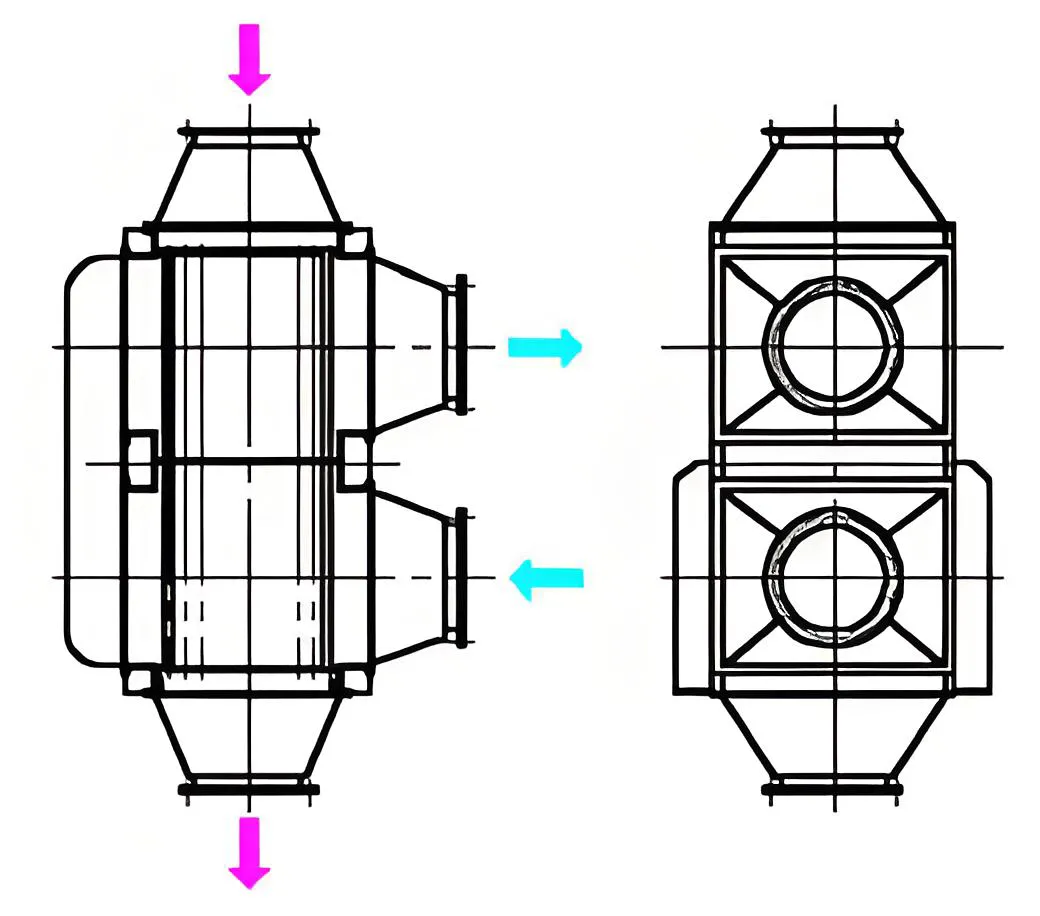

This product is primarily designed for heat recovery between gases and is suitable for scenarios involving the treatment of waste and industrial waste. The maximum temperature at the heat release inlet reaches 850°C. The spiral groove design inside the tubes optimizes heat transfer, while also providing advantages such as dust resistance, lightweight construction, and resistance to low-temperature corrosion.

1.High Heat Transfer Efficiency:

The spiral grooves inside the tubes enhance the boundary film coefficient, significantly reducing the required heat transfer area.

2.Adaptable to Complex Conditions:

The design prevents dust adhesion, maintains a high tube wall temperature in high-temperature scenarios, and overcomes low-temperature corrosion.

3.Easy Maintenance:

In dusty environments, dust protection equipment can be used to reduce maintenance work.

4.Lightweight Design:

The equipment is lightweight, making installation and operation more flexible.

|

Sludge Treatment |

Chemical Industry |

1.Sludge Treatment:

Equipment for human and industrial sludge treatment, wastewater sludge treatment equipment.

Incineration and Furnace-Related: Garbage incineration equipment, industrial waste incineration equipment, industrial furnace waste heat recovery equipment.

2.Chemical Industry:

Equipment used in chemical plant production processes.