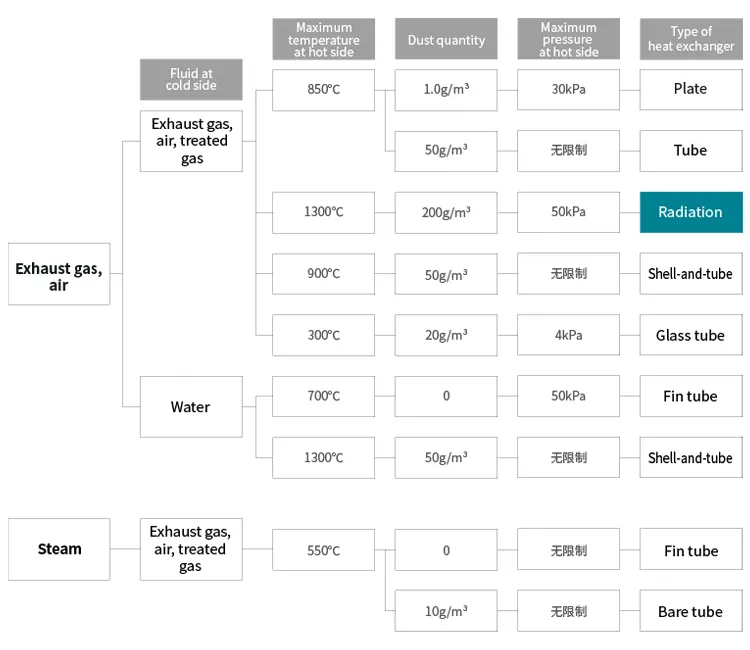

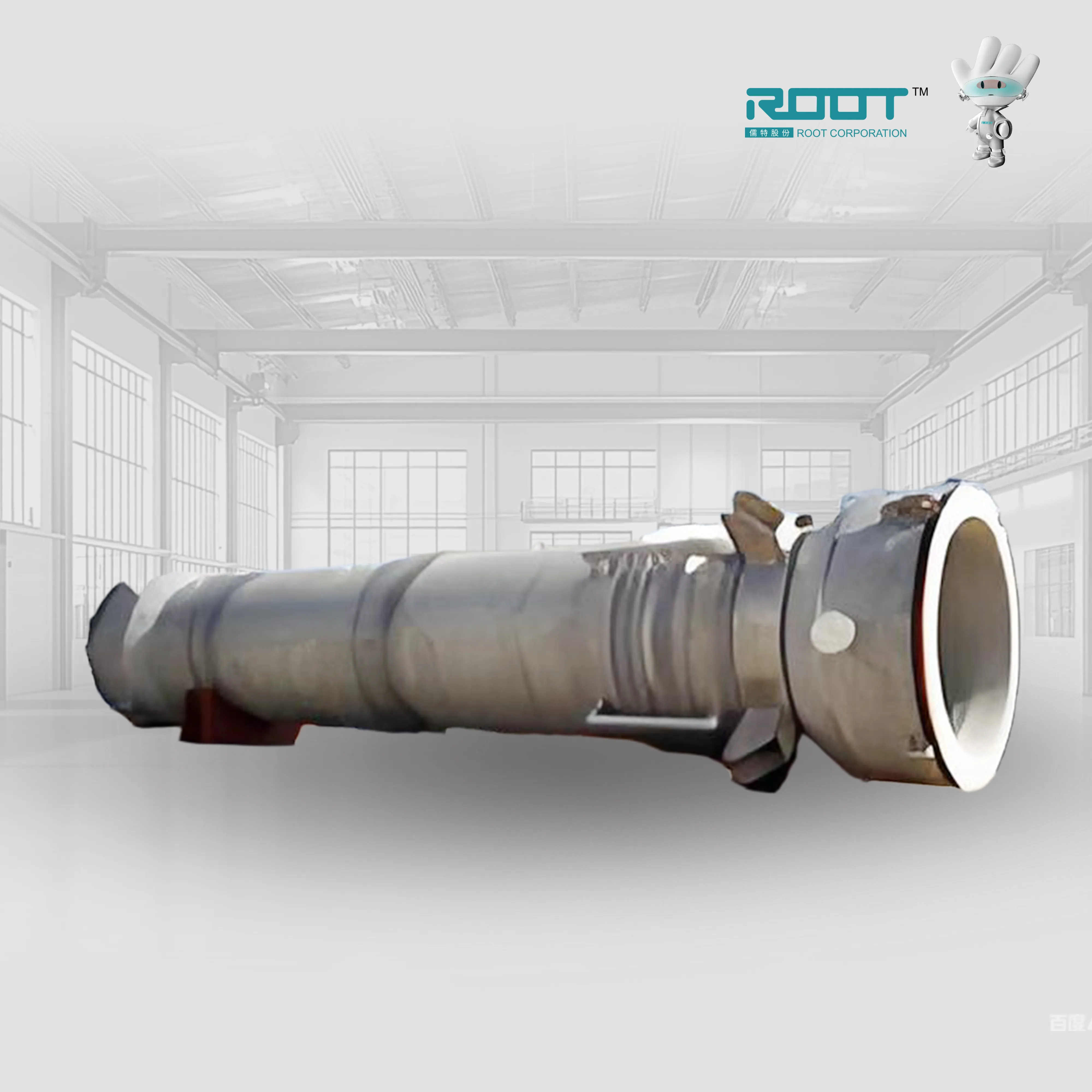

Radiant Heat Exchanger

Suitable for heat recovery in scenarios with high dust content and high temperatures, with exhaust temperatures up to 1300°C, compatible with various industrial environmental protection equipment.

This heat exchanger is designed for heat recovery in environments with high dust content and high temperatures, with exhaust temperatures reaching up to 1300°C. If the high-temperature exhaust gas contains CO₂ and H₂O, infrared radiation will be generated, transferring heat to the heat transfer surface and meeting the heat exchange requirements of specific working conditions.

1.Strong adaptability to working conditions:

Specifically designed for environments with high dust content and high temperatures, capable of meeting the heat recovery needs under such complex conditions.

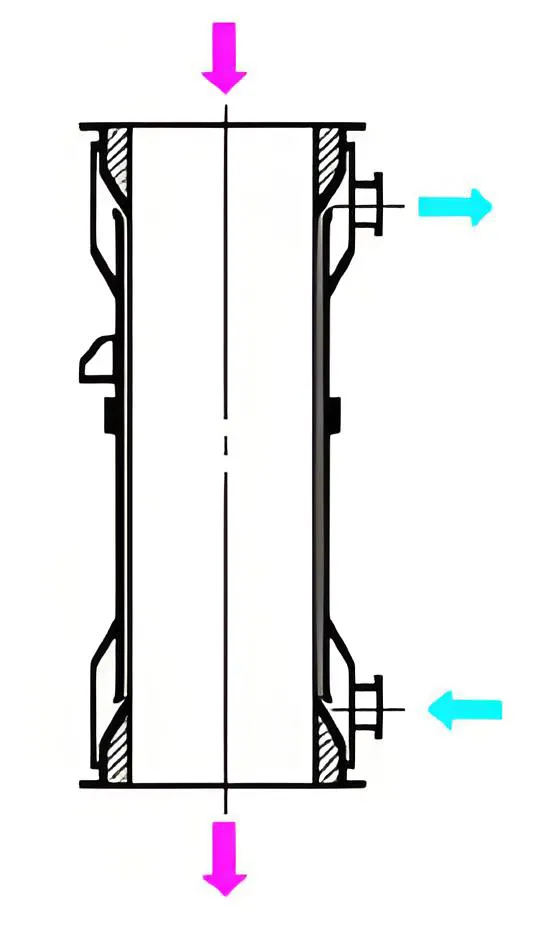

2.Unique heat transfer method:

Uses infrared radiation generated by CO₂ and H₂O in high-temperature gases to transfer heat, without relying on high-speed gas flow.

3.Low operational resistance:

High-temperature gas does not need to flow rapidly, resulting in low gas pressure loss, reducing energy consumption and operational burden.

4.Excellent anti-clogging capability:

No need to worry about dust blockage, reducing equipment maintenance frequency and risk of failure.

(Image in the performance features folder)

|

Sludge treatment |

Energy recovery |

Waste treatment |

1.Sludge treatment:

Industrial waste sludge treatment equipment, sewage sludge treatment equipment

2.Energy recovery:

Industrial furnace waste heat recovery equipment

3.Waste treatment:

Waste incineration equipment, industrial waste incineration equipment