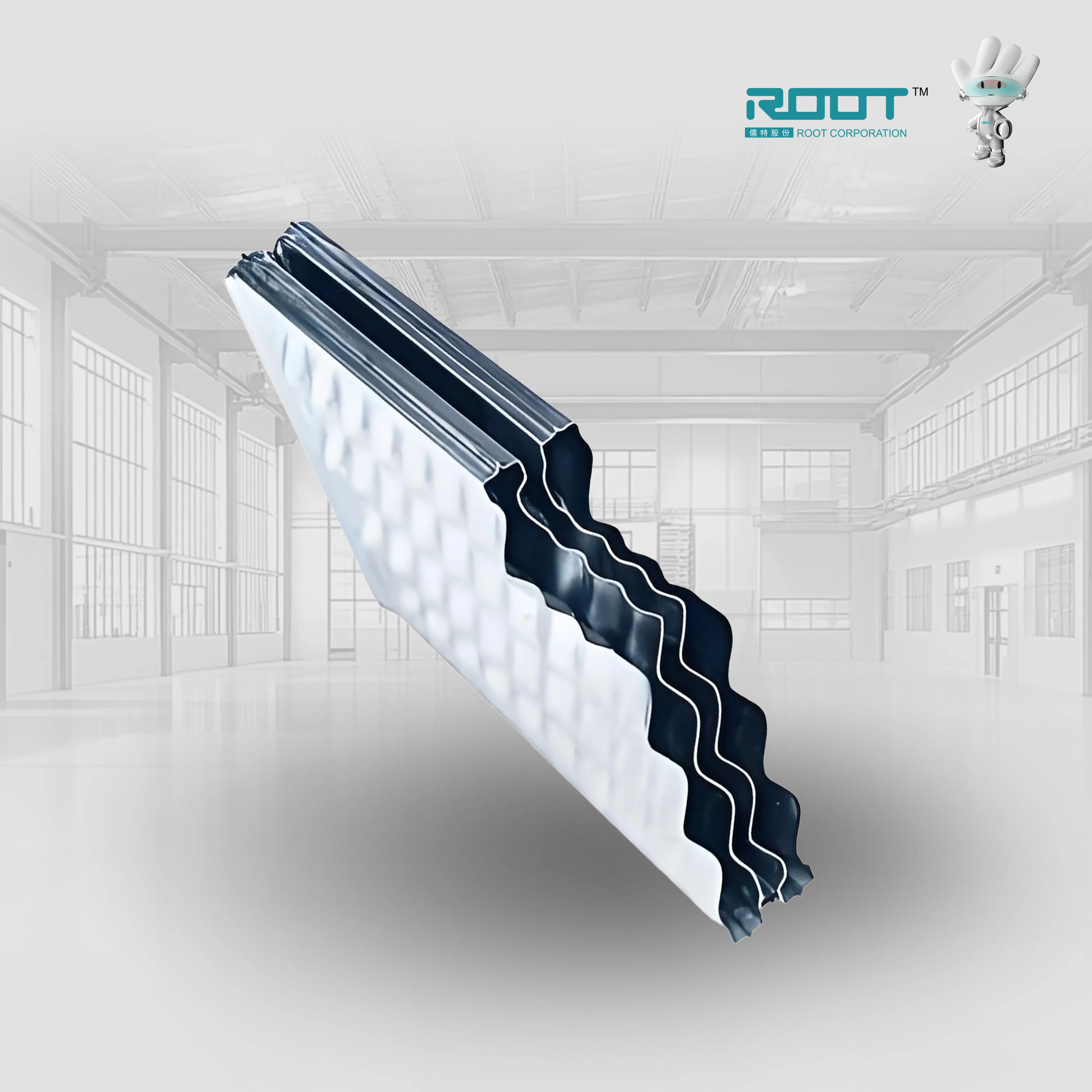

Heat Transfer Plate

The product type is HINO-PILE single plate, which is a core component of heat exchangers. It is made by welding corrugated metal plates together and can be combined into heat exchangers with different flow patterns, serving as a replacement for traditional equipment.

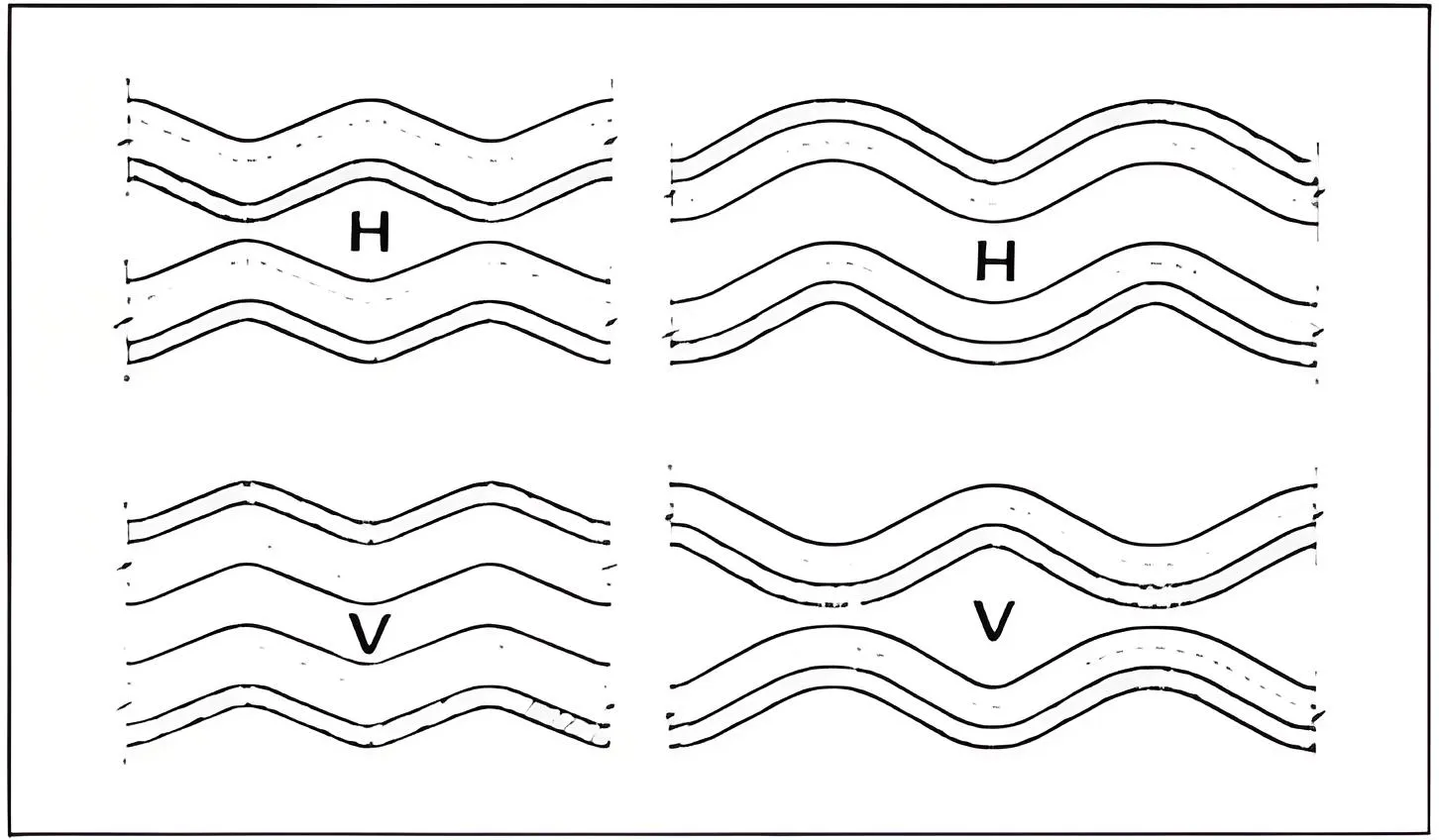

Each single plate consists of two vertically and horizontally corrugated metal plates welded together as a set, combined with expansion joints to form vertical flow or counter-flow heat exchangers. The fluid passages are specially designed, offering high heat transfer efficiency and compact size, making them suitable as replacements for old-style coil or finned tube heat exchangers.

1.Wide application range:

Compatible with gas-gas, gas-liquid, liquid-liquid, and other heat exchange forms, covering various industrial sectors.

2.Durable and stable performance:

The fluid exhibits high turbulence, the heat transfer coefficient is large, and fouling is hard to adhere, maintaining high performance over the long term.

3.Compact design:

Provides a larger heat transfer area per unit volume compared to multi-tube designs, with a high overall heat transfer coefficient and small equipment footprint.

4.Low flow resistance:

Fluid travels a short distance, and plate spacing can be adjusted according to pressure loss requirements.

5.Excellent pressure resistance:

Plate wave peaks contact design, with customizable frame structure for required pressure tolerance.

6.Easy maintenance:

No moving parts, simple construction, easy to clean, and low maintenance frequency.

7.Good heat resistance:

Made of heat-resistant steel and welded assembly, with high tolerance to thermal expansion differences.

|

industrial machinery |

mining |

construction |

power |

automotive |

chemical |

food industries |

Covers all industrial sectors including industrial machinery, mining, construction, power, automotive, chemical, and food industries. Suitable for heating, cooling, condensation, evaporation, and various other heat exchange scenarios.