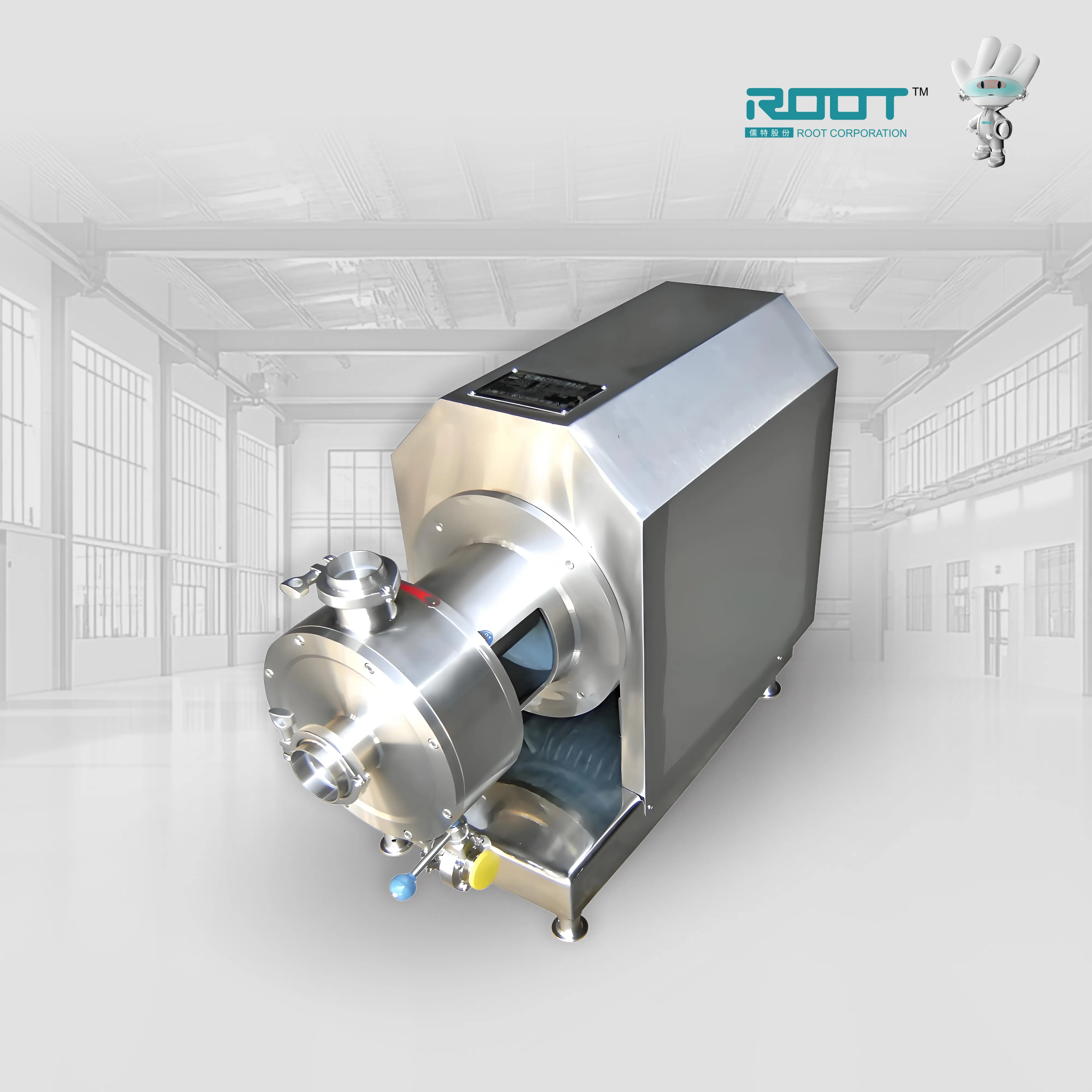

RTRB High-Shear Emulsifying Pump

This is a high-efficiency mixing equipment. Generating strong shearing force through the rotor-stator, it outperforms low-speed stirring in efficiency, is suitable for high-viscosity materials, and features high shear rate, low energy consumption and easy maintenance. Multiple models are available for various industries.

A high-shear emulsifying pump is a high-efficiency mixing device, whose core working components consist of a high-speed rotating rotor and a fixed stator. By generating enormous shear force, it instantly tears and breaks down materials, thereby achieving fine emulsification, homogenization, and efficient mixing of materials. It is a key device for preparing stable and uniform emulsions and suspensions.

|

coatings |

inks |

cosmetics |

food |

pharmaceuticals |

It is suitable for industries such as coatings, inks, cosmetics, food, and pharmaceuticals.

|

Model |

Power(kW) |

Rotational Speed(rpm) |

Throughput(L/h) |

Inlet |

Imported |

|

RTRB-1.5 |

1.5 |

0-2950 |

0-1.5 |

DN32 |

DN25 |

|

RTRB-2.2 |

2.2 |

0-2950 |

0-3 |

DN32 |

DN32 |

|

RTRB-4 |

4 |

0-2950 |

0-4 |

DN40 |

DN40 |

|

RTRB-5.5 |

5.5 |

0-2950 |

0-5 |

DN50 |

DN40 |

|

RTRB-7.5 |

7.5 |

0-2950 |

0-8 |

DN50 |

DN40 |

|

RTRB-11 |

11 |

0-2950 |

0-12 |

DN60 |

DN50 |

|

RTRB-15 |

15 |

0-2950 |

0-18 |

DN60 |

DN50 |

|

RTRB-22 |

22 |

0-1450 |

0-25 |

DN60 |

DN50 |

|

RTRB-30 |

30 |

0-1450 |

0-35 |

DN80 |

DN60 |

|

RTRB-45 |

45 |

0-1450 |

0-50 |

DN125 |

DN80 |

|

RTRB-55 |

55 |

0-1450 |

0-75 |

DN125 |

DN80 |

|

RTRB-75 |

75 |

0-1450 |

0-90 |

DN150 |

DN125 |